Category

Download Catalog

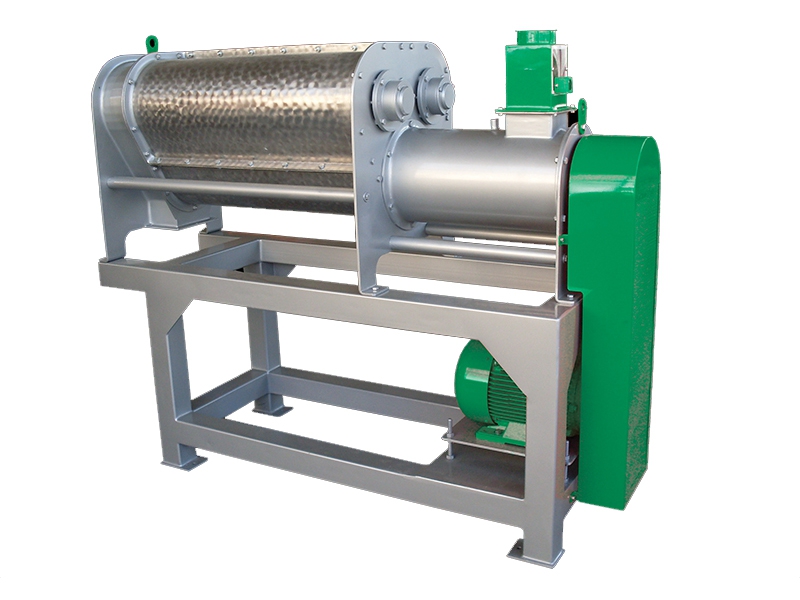

Product Description

PROPERTIES

It is used in the cereal processing facilities for the purpose of ensuring the required humidity rate to get penetrated into the cereal.

It is made of corrosion-proof, solid material (HARDOX) angled with proper measurements on the rotor placed inside the angled, semi-cylindered body of stainless steel (Cr-Ni).

While the cereals are carried upward with pallets, they are subjected to an intensive mixing with a measured pace and water is ensured to be absorbed by the cereals.

The machine consists of two main structures; the body on legs contains a rotor carrying anchors, a driving motor, a cover, an inlet and outlet controlled by a material transition sensor.

A rotor is a part assembled to the body with two strong roller bearing systems and containing detachable pallets suitable for vibration-free running because of balance calibration.

ADVANTAGES

High Quality, High Performance, High Yield, High Capacity, Long Life, High Precision

Maximum Usability, Minimum Periodic Maintanence, Minimum Energy Consumption, Minimum Sound Level

USAGE AREAS

- Food Industry

- Flour and Semolina Plants

- Other Food Processing Facilities

- Technical Specifications

- Technical Image

- Brochure

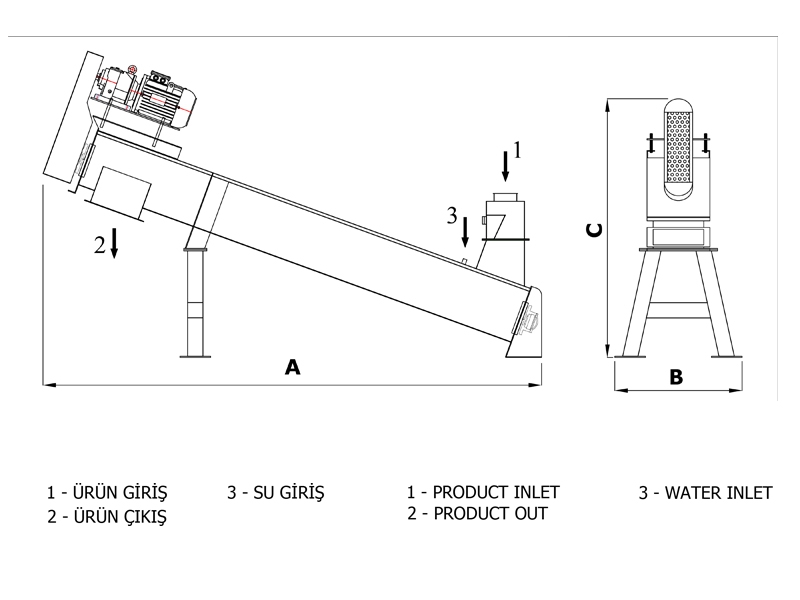

| TYPE | DIMENSIONS (mm) |

Amount of Water Loss | Power | Capacity | Weight (kg) |

Volume | ||

| A | B | C | (lt/h) | (kw) | (t/h) | Net | (m3) | |

| A T - 250 | 3250 | 680 | 1580 | 500 - 600 | 4 | 6 - 8 | 380 | 2,2 |

| A T - 300 | 3250 | 730 | 1680 | 600 - 800 | 4 | 10 - 12 | 400 | 2,5 |

| A T - 400 | 3250 | 930 | 1720 | 750 - 1000 | 5.5 | 15 - 20 | 580 | 2.8 |