Category

Download Catalog

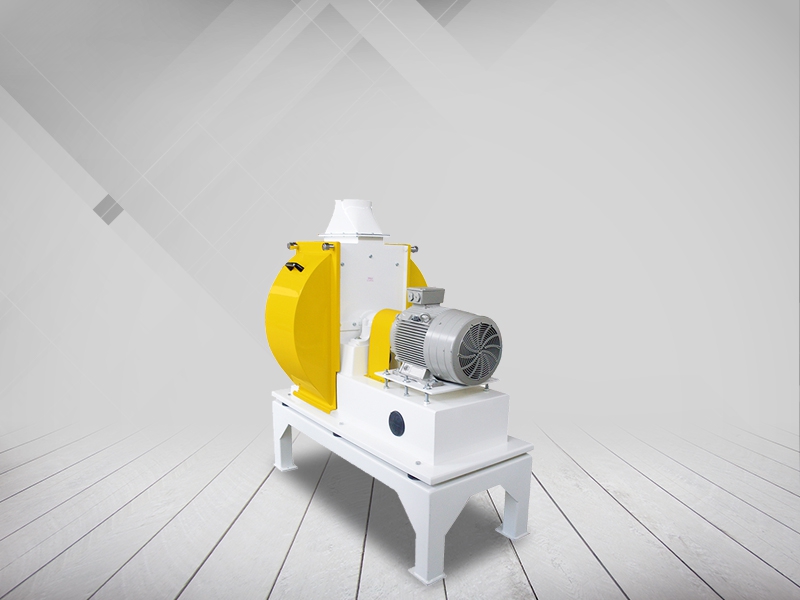

Product Description

APPLICATION

Hammer mili can beusedalsoin;maizemill, animalfeedandsomefood industries. Highest efficiency can be grained by using max.50 mm, sized particles 0.2 ~ 0.8 kg/dm3 density and humidity rationothigherthan%16 raw materials.

WORKING PRINCIPLE AND CONSTRUCTION

The material is dropped regularly in to the grinding section always must use inlet magnett. The material, broken by the impactive effect of the hammers, can be broken to the demandet size by suitable sieve selection. The main body the motor tripod and the chassis are heavy can struction. The sieves and the hammers can be changed easily through thesidecovers so there isn't any loss of time. The rubber pieces under the chassis prevent the floor from taking.

- Technical Specifications

- Technical Image

- Brochure

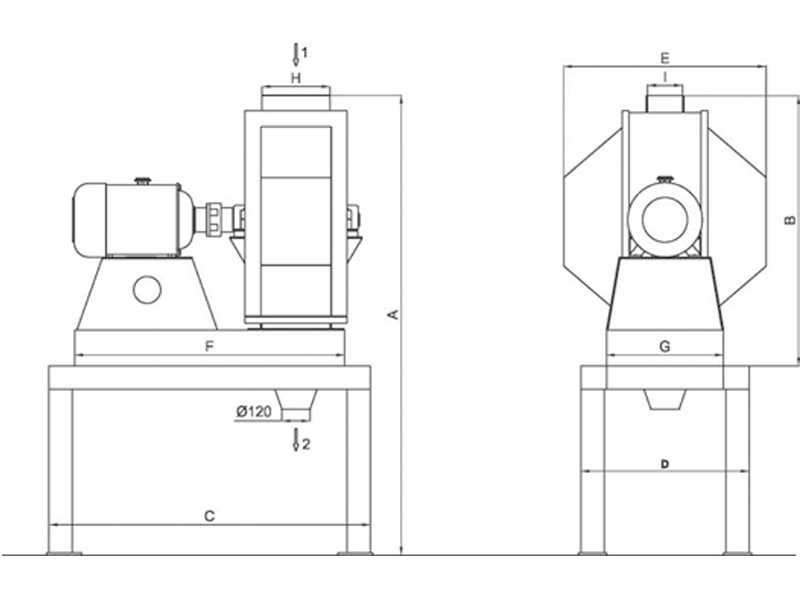

| TYPE | Dimensions (mm) |

Capacity (kg/h) |

Power (kw) |

Weight (kg) |

||||||||

| HM-11 | A | B | C | D | E | F | G | H | I | |||

| 1970 | 1157 | 1375 | 720 | 865 | 1155 | 500 | 290 | 150 | 600 | 11-15 | 275 | |

| HM-22 | 2120 | 1310 | 1645 | 810 | 965 | 1430 | 610 | 400 | 165 | 2200 | 18.5-22 | 385 |